Use compacer's monitoring solutions for preventive maintenance and condition monitoring of your systems

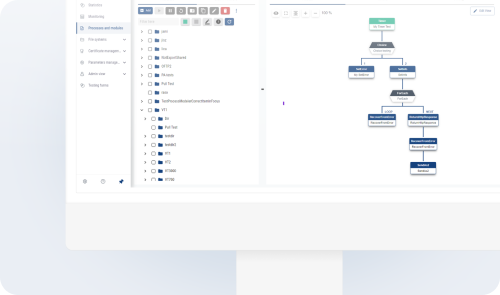

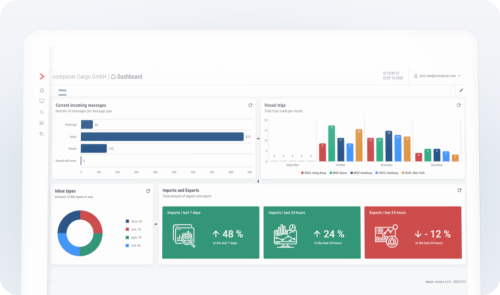

With our in-house software, edbic and edpem, you benefit from continuous data acquisition and analysis, providing in-depth insights into the system status at any given time. Use compacer for process automation, preventive maintenance, and as a data-driven approach for predictive maintenance.