We connect machines and systems for Industry 4.0

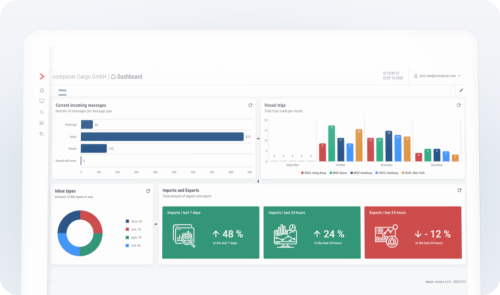

An IIoT gateway serves as a connecting element between operating technology and IT systems by securely and reliably connecting networks and data points and simplifying the maintenance and servicing of your systems.

As a flexible IIoT gateway, compacer edbic seamlessly connects your old and new technologies and makes in-house machine-to-machine communication a breeze.

Connect, analyse, and optimise your data digitally with edbic and remain loyal to your familiar hardware.