Family business Blickle relies on condition monitoring with edbic

/Blickle/download-removebg-preview.png)

/Blickle/download-removebg-preview.png)

As a modular system, edbic can be easily adapted and further developed at any time. The platform can be used not only for condition monitoring but also as an IoT gateway. The high degree of automation optimizes the maintenance effort of the machines and leads to fewer manual errors.

"With edbic, we have not only introduced a modern condition monitoring system that allows us to make the best possible use of our machine data. We have also created the basis for predictive maintenance and other digitalization projects."

"Since we have been using compacer, it has become much easier to integrate new machines into production. As soon as the machines are integrated into our condition monitoring, they are also automatically connected to all other systems - including SAP."

Interview

Interview

An interview with Christian Bertels from the wheel and castor specialist Blickle about the challenges of digitalisation in the manufacturing industry.

White paper

White paper

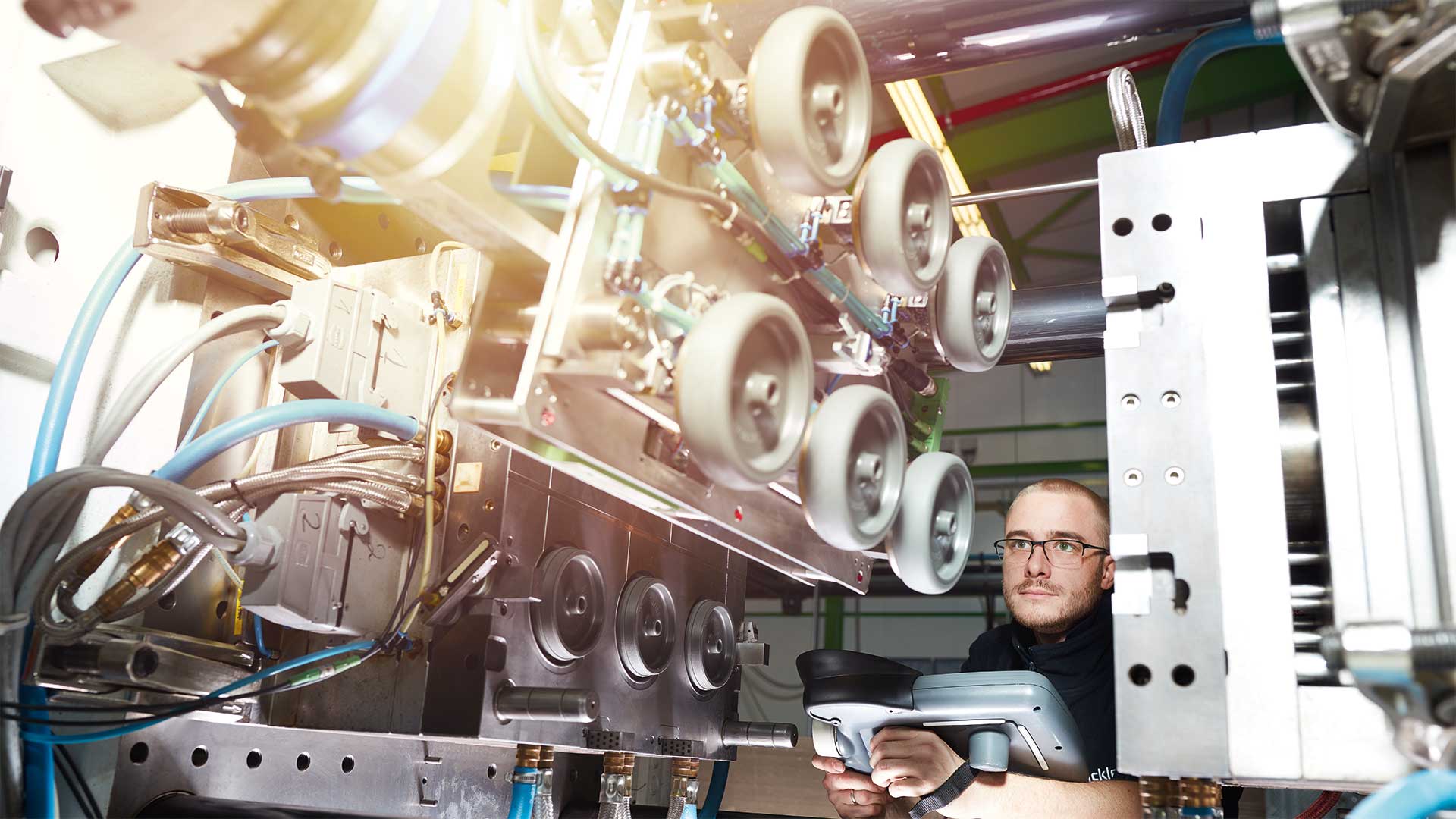

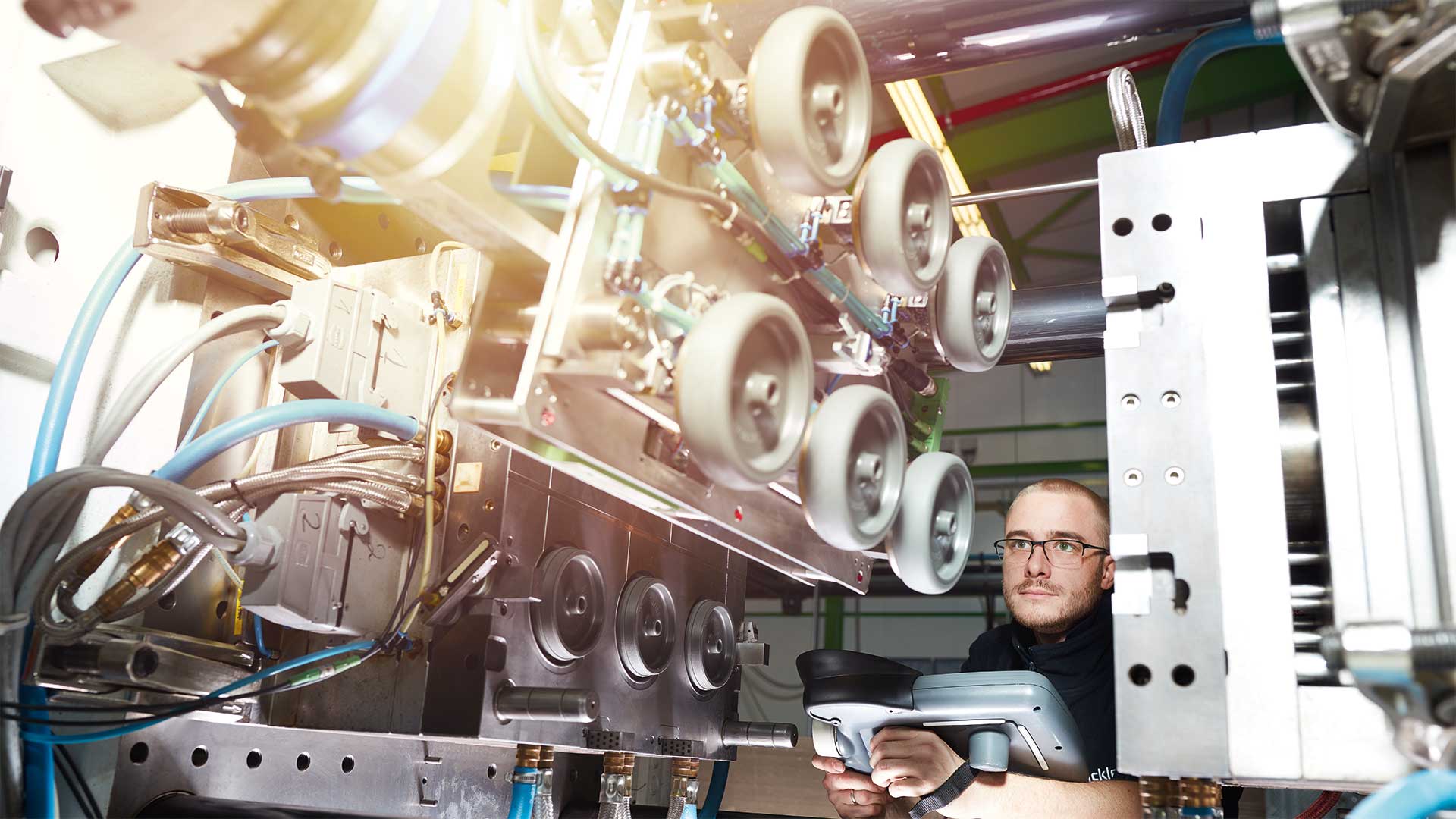

Blickle ensures greater transparency and faster response times with edbic. Condition monitoring as a prerequisite for Industry 4.0.

Whitepaper

Whitepaper

In a production process geared towards efficiency and productivity, the individual production steps are closely interlinked. The sudden unexpected failure of a machine or component can bring the entire production line to a standstill.

Whitepaper

Whitepaper

In many manufacturing companies, heterogeneous production environments have grown over time and there are many systems with a low level of automation. These now need to be integrated into the new digital world.

Are you also thinking about connecting the old world with the new via an IT integration project?