Perheyritys Blickle luottaa edbicin kunnonvalvontaan

/Blickle/download-removebg-preview.png)

/Blickle/download-removebg-preview.png)

Modulaarisena järjestelmänä edbic voidaan helposti mukauttaa ja kehittää edelleen milloin tahansa. Alustaa voidaan käyttää kunnonvalvonnan lisäksi myös IoT-yhdyskäytävänä. Korkea automaatioaste optimoi koneiden huoltotyöt ja vähentää manuaalisia virheitä.

"edbicin myötä olemme ottaneet käyttöön modernin kunnonvalvontajärjestelmän, jonka avulla voimme hyödyntää konetietojamme parhaalla mahdollisella tavalla. Olemme myös luoneet pohjan ennakoivalle kunnossapidolle ja muille digitalisaatiohankkeille."

"Kun olemme käyttäneet compaceria, uusien koneiden integrointi tuotantoon on helpottunut huomattavasti. Heti kun koneet on integroitu kunnonvalvontaan, ne yhdistetään automaattisesti myös kaikkiin muihin järjestelmiin - myös SAP:iin."

Haastattelu

Haastattelu

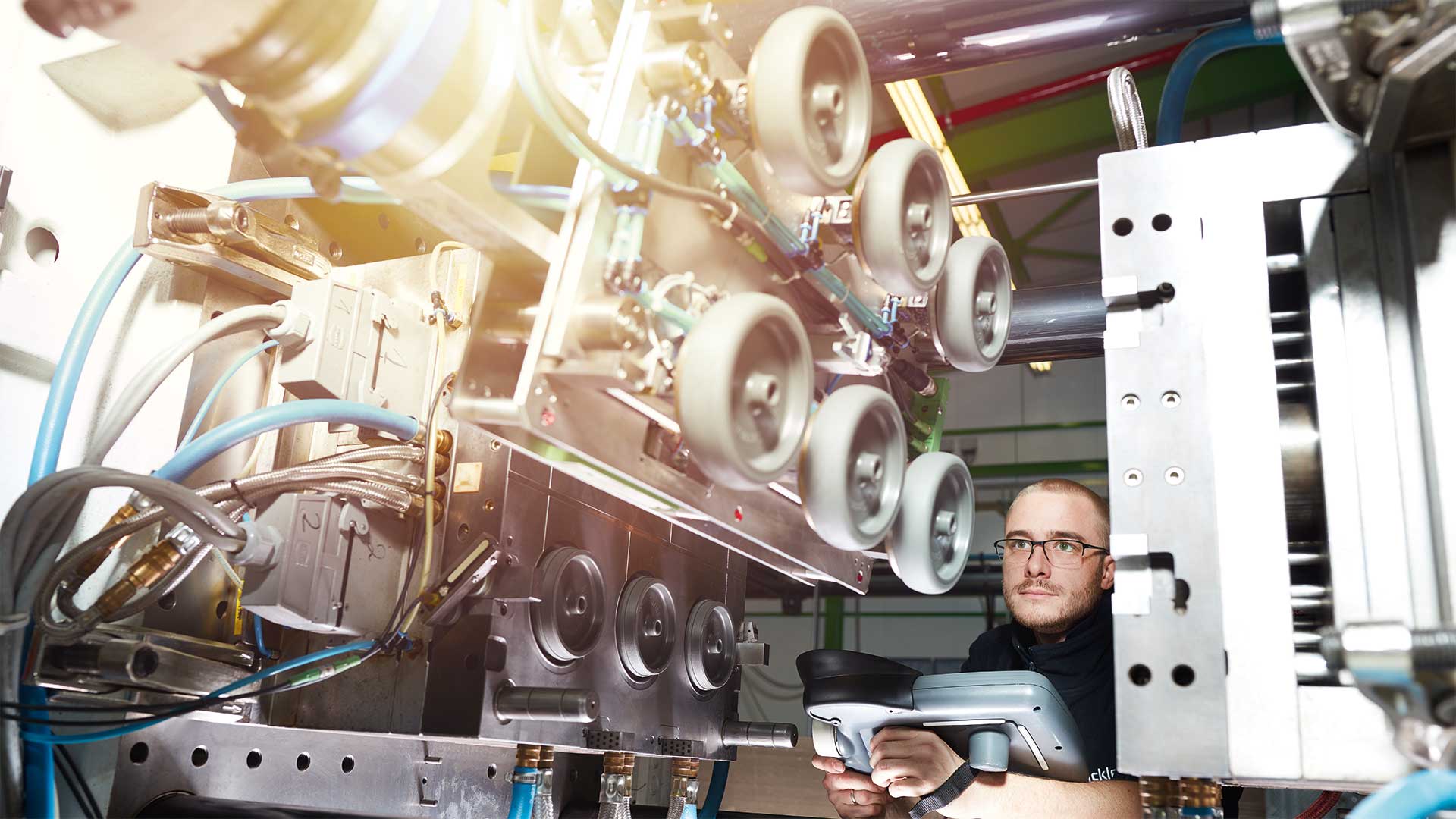

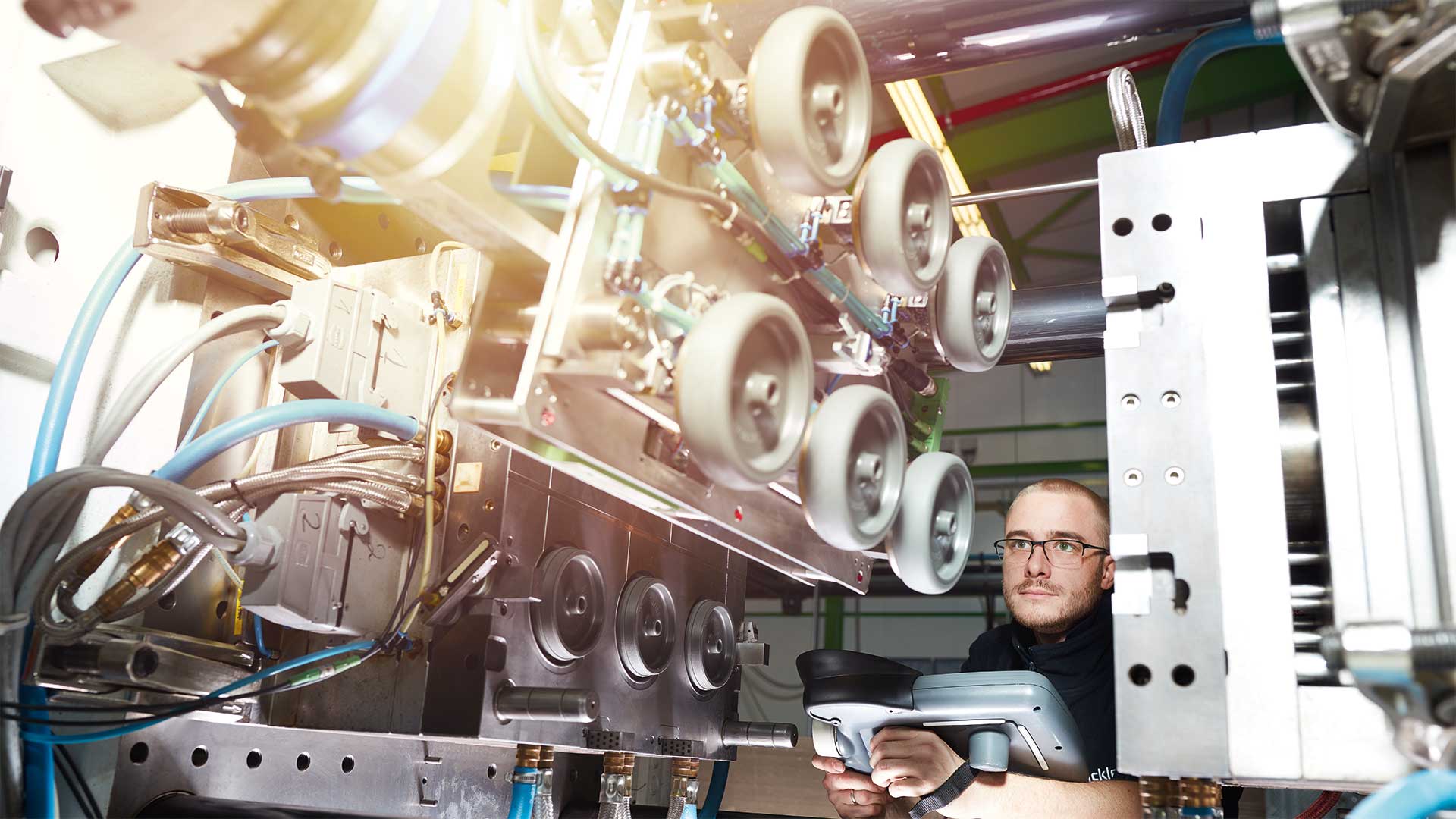

Christian Bertelsin haastattelu pyöriin ja valurautoihin erikoistuneelta Blickle-yritykseltä digitalisaation haasteista valmistusteollisuudessa.

Valkoinen paper

Valkoinen paper

Blickle varmistaa suuremman läpinäkyvyyden ja nopeammat vasteajat edbicin avulla. Kunnonvalvonta on teollisuus 4.0:n edellytys.

Valkoinen paperi

Valkoinen paperi

Monissa valmistusyrityksissä heterogeeniset tuotantoympäristöt ovat kasvaneet ajan myötä ja monissa järjestelmissä on alhainen automaatioaste. Ne on nyt integroitava uuteen digitaaliseen maailmaan.

Valkoinen paperi

Valkoinen paperi

Monissa valmistusyrityksissä heterogeeniset tuotantoympäristöt ovat kasvaneet ajan myötä ja monissa järjestelmissä on alhainen automaatioaste. Ne on nyt integroitava uuteen digitaaliseen maailmaan.

Harkitsetko myös vanhan maailman yhdistämistä uuteen IT-integraatioprojektin avulla?